As business and residential networks rapidly go the wireless route, industrial networks are following the trend. Research interest focuses on exploration of integration of wired and wireless communications from the factory and process automation viewpoint to improve decision making on the timing and strategy for implementing wireless networks for automation projects.

Going wireless is more than just plugging in some wireless components to replace the wires. Residential networks are easily justified using today’s inexpensive wireless components to avoid costly or unsightly wire installations. Business offices usage is not quite so clear due to the known privacy and coverage problems and the generally lower cost of running office wiring.

Subject to the same problems, industrial use must have secure communications that never fails. The cost of industrial wiring is so high, however, that wireless can usually be justified.

Mathematical analysis and modeling of wireless communication must be also combined with signal measurements and protocol testing and harnessing in noisy industrial areas in which these networks have to prove its reliability and availability beside cost cutting in comparison to cable networks.

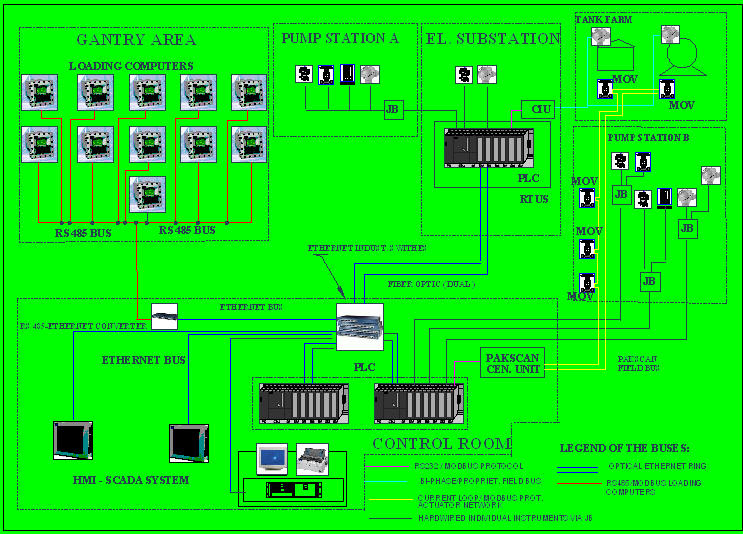

But going wireless is not the only way to cut on expensive hardwired interconnection between the individual devices in the field and main control room equipment, which these days are, without exception, computer based HMI systems. Even hard wired networking in industrial environment using a variety of field buses, still striving to standardize on protocols, are bringing tremendous cuttings in cabling and marshalling costs, while providing, through employment of diversity of redundant architectures, high level of system integrity and reliability. Good example for this is the topology of the monitoring and control system designed at this Laboratory for overhauling and revamping of the part of Refinery complex, encompassing refinery products truck loading station with tank farm and pipeline delivery metering and shipping station.

As can be seen on the following figure, the overall network includes : the multimode fiber optic ring with Ethernet protocol as the backbone, and three communication branches consisting of RS 485 and proprietary based field busses, interconnecting individual devices and clustering them throughout the plant area and then bringing data from each of them to control room and making them available for central process database implemented within Web based HMI system. These three clusters of field busses are collecting 60 devices in the local network of actuators, 12 of product loading computers, and 8 of level gauges on tanks and spheres. In contrast to using field buses, bringing each of these instruments to connect to HMI computer in the control room, would require additional marshalling cabinet in the control room and more then 800 pairs of cable wires of various length varying from 40- 300 m, adding to that almost the same number of analog and digital I/O channels in computer interface to introduce them to computer memory for signal processing. Cost savings are more than obvious, not to mention the wealth of additional information that digital communication via field buses can bring to central computer, like diagnostics data on each instrument, remote calibration and maintenance, etc..